Secrets Behind How Diamonds Are Cut

June 25th, 2019 / Lindsay Kazan

Contrary to popular belief, a diamond’s cut grade is the most important of the four quality characteristics of diamonds to consider when purchasing a stone. How diamonds are cut has the largest impact on a stone’s ability to sparkle and shine, which has the power to make even the highest quality diamond appear dull and lifeless if it’s cut poorly. Of all of the four main diamond quality ratings, the cut is the most complex and difficult to analyze as it’s very technical and requires precise measurements. Understanding the intricacies of this process can help you when purchasing diamond alternative jewelry and ensure you walk away with the diamond of your dreams. Now let’s get to it; how are diamonds cut?

HOW DO YOU CUT DIAMONDS?

The goal of the diamond cutting process is to take a rough diamond stone – whether natural or lab grown diamonds – and change its shape into that of a beautiful gem ready to be set in jewelry. Though diamonds are one of the hardest materials in the world, the cutting process is extremely delicate as one small incorrect angle could drastically impact the diamond’s final value. For this reason, diamonds are always cut by trained professionals with expert knowledge and access to sophisticated equipment and tools. As a result of the diamond’s hardness, a stone can only be cut using another diamond, so a cutter’s tools usually consist of diamond-bladed edges or discs that are lined in diamond dust. Lasers are also used on occasion, but generally not until the later stages of the process.

How to cut a diamond really comes down to five steps:

Planning. Creating a precise plan to cut a diamond is one of the most important steps to get right. Though it’s a time-consuming process, it sets the cutter up for success and helps to avoid mistakes that would otherwise impact the diamond’s final value. As the cutter determines the shape of the diamond that can be produced, he will consider how best to minimize waste and maximize the yield of the rough stone.

Using a machine, such as a Sarin, to map out accurate measurements, the stone cutter will then input the data into computer software that can help generate 3D models of the cutter’s options. This will help them to determine the best shape to create the final product and ensure the proportions of the facets are correct. All of this planning helps the cutter to ensure that the final diamond they produce is symmetrical and of the highest quality cut possible.

Cleaving. This next step of the process splits the rough stone into separate pieces, allowing the cutter to fully utilize the rough. Each piece can be worked on individually to yield the highest quality diamond possible. Traditionally, this can be done using mechanical saws, but if a rough is oddly shaped, contactless lasers may be used to increase the precision of cleaving.

Bruting. Once the large rough is split, bruting will further separate the pieces into rough stone rounds. Also known as girdling, this process involves placing the two diamond roughs next to each other on a spinning axle, then turning them in opposite directions to grind against one another. This creates what is known as a rough girdle finish and will help the final diamond begin to take shape.

Polishing. After the rounded shape of a diamond has been formed, the cutter must create the multiple facets that give a diamond its signature look and shine. Placing the rough on a rotating arm, they will use a spinning wheel to polish it and produce smooth, reflective facets. This stage of diamond cutting can be further divided into two steps: blocking and brillianteering. When blocking, the cutter will make some of the primary cuts that create a single stone and essentially make a template for the following stage. A brillianteer will then finish the stone cutting process by refining these cuts and adding more facets to give the diamond fire and brilliance, ultimately determining the final value of the diamond.

Inspecting. The final step in how to cut diamonds is a quality control check and inspection. If certain specifications were set by a manufacturer, the diamond will be measured against them and sent back to the polishers for touch-ups if needed. Otherwise, it will be cleared to move on to grading and certification.

ANATOMY OF A DIAMOND

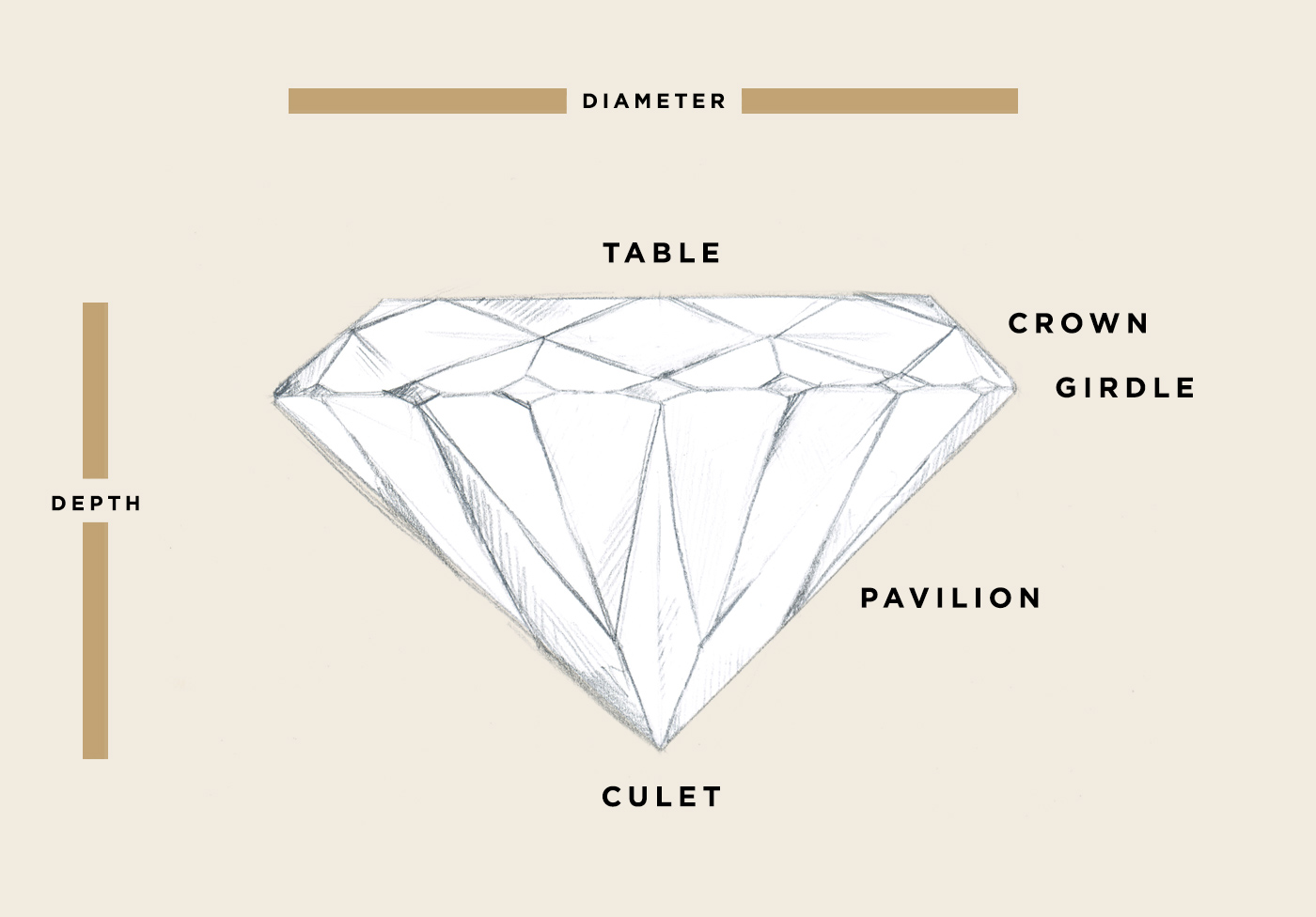

Though every diamond is unique, they all share certain structural features which have a direct impact on their shape and cut grading. Each part of a diamond’s anatomy has a specific name, and understanding how each of these parts contributes to the diamond as a whole will help you find your perfect diamond.

A diamond is comprised of the eight main components:

- Diameter: The width of the diamond as measured from edge to edge.

- Table: The largest polished facet as seen on the top of the diamond.

- Crown: The angled top part of the diamond extending from the table to the girdle. It is comprised of bezel facets (sometimes known as crown mains), star facets, upper girdle facets (also known as upper halves), and the table.

- Girdle: The widest edge of the diamond where the crown and pavilion meet.

- Pavilion: The lower half of the diamond which extends from the girdle to the culet.

- Depth: The depth is determined by the total height of the diamond as measured from the table to the culet.

- Culet: The small point at the very bottom of the diamond.

Developing a basic understanding of a diamond’s anatomy will allow you to truly appreciate a diamond and all its intricacies. It can also help you when you’re wondering how to shop for diamonds because you’ll be able to communicate more effectively with experts about a particular diamond when shopping. Whether you’re wondering what is a solitaire diamond and how cut impacts that style, or are interested in learning more details about the cut of specific diamonds, this information will equip you for any conversation. Most importantly, it will help you to make a well-considered decision regarding the diamond that is best for you, your style, and your budget.

THE DIAMOND CUT GRADE SCALE

Once a diamond is cut and inspected, it will be graded. The widely accepted standard for cut grades was developed by the Gemological Institute of America (GIA) and takes into account the design and craftsmanship of each diamond. Using a precise calculation, the scale evaluates a diamond’s weight relative to its diameter, girdle thickness, the symmetry of its facet arrangement, and quality of the polish on those facets. The GIA scale is specifically designed to grade standard round diamonds, the most common shape, with color grades ranging from D to Z, though it can be used to assess other shapes as well.

This scale also considers how the proportions of the diamond influence certain visual effects produced by the diamond when it interacts with light. This includes:

- Brightness: How white light is reflected from a diamond internally and externally.

- Fire: How and if the diamond scatters white light into all the colors of the rainbow.

- Scintillation: The sparkle a diamond produces, as well as the pattern of light and dark areas produced by reflections within the diamond.

Evaluating all these factors, a skilled grader will give each diamond one of six distinct grades on the GIA cut scale:

- Ideal: Stones with this cut will have an exceptional level of craftsmanship. These stones emit the most light dispersion and brilliance (thereby also causing it to be the highest value and price as well).

- Excellent: Diamonds of this grade have an excellent level of craftsmanship and emit a great amount of brilliance and light dispersion. Stones of this grade will also result in higher prices.

- Very Good: These diamonds will still have high marks for scintillation and brightness, but the diamond’s proportions will increase the darkness seen in its face-up appearance or may result produce splintered scintillation.

- Good: Bad proportioning of the diamond’s angles will produce scintillation issues that may manifest as a lack of contrast in the face-up pattern or general darkness within the stone making it appear dull.

- Fair: Like those with a good cut grade, a diamond with this grade will have localized darkness in its facets and a lack of internal contrasting, producing a diamond with very little shine.

- Poor: A poor cut grade diamond will mostly appear dark and dull. This is often the result of a thick girdle and angles that are too steep. Diamonds with this grade will usually have a diameter that is smaller than its carat weight would otherwise suggest.

DIAMOND CUT + PRICE

Natural diamonds with an Ideal Cut are very rare and likely account for less than 3% of all diamonds. As a result, they have the highest value and will be priced accordingly. The majority of diamonds sold will probably have a cut grade of Good or Very Good, which represent a great combination of beauty and value. Most jewelers choose not to sell lower grades due to the quality. Additionally, if you purchase a higher cut grade diamond, you may be able to more easily compromise on other characteristics such as color or clarity.

When you’re shopping for diamond jewelry, you may also consider a diamond alternative like Diamond Nexus. Our lab created diamond alternatives are made using a patented formula designed to simulate the look, weight, and wear of a natural diamond, at perfect quality every time. Every Nexus Diamond™ alternative has an Ideal Cut grade from the GIA, is completely colorless, and has IF clarity. Since they’re lab created, our diamond alternatives are up to 80% less than mined diamonds because we believe you should not have to sacrifice quality for budget. Plus, we guarantee our diamond alternatives for life so you can purchase with confidence, knowing you’ll have the greatest sparkling stone forever!

*Diamond Nexus strives to provide valuable information, while being clear and honest about our products. The Nexus Diamond™ alternative is a patented lab created diamond simulant that, among all simulants, most closely imitates the look, weight and wear of a diamond, with two exceptions – it is absolutely perfect in every way, and it costs significantly less. Price points and environmental facts expressed in this blog were taken from popular online retailers and may vary. Learn more about the environmental impact of mining by visiting our blog.